M.Sc. thesis worker

VTT

In Summer 2022 I was offered a chance to do my master’s thesis in MASCOT project at VTT. As the themes of the project immediately caught my interest, I decided to pursue the thesis as a part of MASCOT. I was excited to be working on a sustainability-centred project on solving the material challenges with new fossil-free process technologies and the topic of my thesis was chosen to be materials for ammonia combustion. Previously I had been involved with biological corrosion of metals at VTT and was eager to start a project with a very different type of topic where I could still utilise many of the same sample preparation and characterisation skills I was familiar with already.

When my thesis project began, the very first part of it was planning out the experiments with the help of my supervisors. Although there obviously was a certain ready framework in the project, I was in many aspects responsible of planning, organising, and scheduling the execution of the experiments. For me personally this was one of the most important learning outcomes of my thesis as I began to comprehend how scientific research projects are coordinated. The project had certain time constraints as most of the experiments should be completed by the end of January before my university exchange would begin. As the sample preparation was known to be time consuming and the longest furnace exposure time was almost six weeks, it was clear that the experiments should start as soon as possible.

Keeping the time constraints in mind, I began working on the sample preparation as soon as the materials were delivered. The sample preparation was the most challenging part of the whole project as I had all together 120 samples and the preparation process was somewhat repetitive. However, I became to better understand the properties of the materials I was working on during the process and also became familiar with all the steps in the sample preparation protocol. This helped me later on both in the sample characterisation but also with the thesis writing itself.

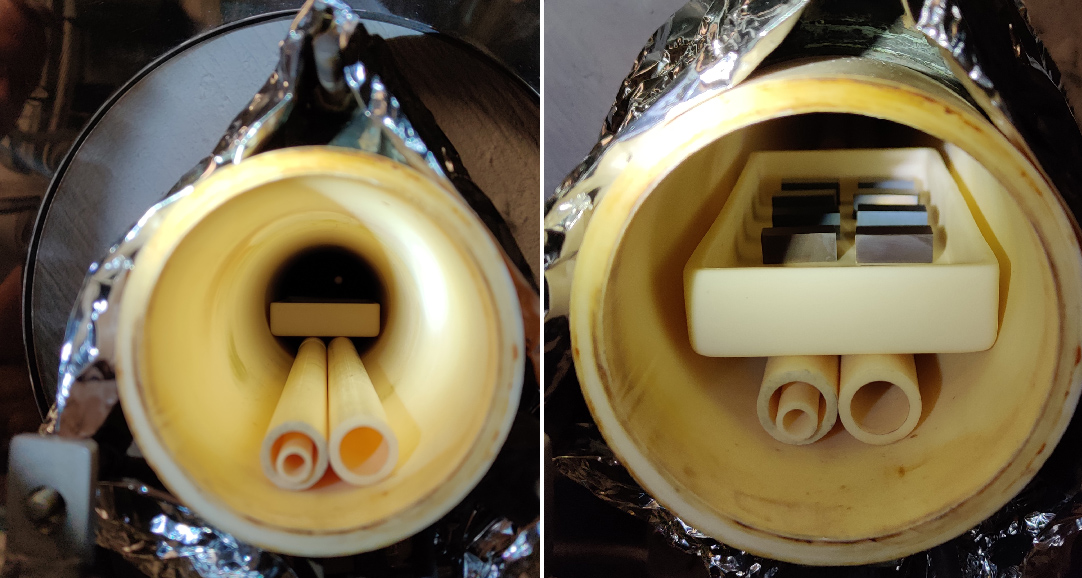

The most interesting and fun parts of the project were implementing and troubleshooting the actual furnace experiments with ammonia and, of course, the post-experiment characterisation. I had previously never been involved with high temperature corrosion experiments or working with hazardous gases, so it was indeed a very exciting learning experience. During the post-experiment sample characterisation, I was very curious to see how the samples had behaved in the experiments. It was fascinating to see the samples in the scanning electron microscope after first executing the whole process from obtaining the materials and preparing the samples to now characterising them after being exposed to high-temperature ammonia. For the first time I had completed an extensive scientific research project from start to finish.

The sustainability point of view in MASCOT was one of the main reasons I became interested in the project in the first place and now it is amazing to think that my work has contributed to this. It is becoming increasingly urgent to find sustainable solutions for the conventional practices, such as in this case aiming to replace carbon containing fuels with ammonia. The relevance of the research in MASCOT was evident due to these sustainability issues in carbon containing fuels, which made the project very rewarding for me. Reminding myself of the significance of the project was an easy task.

Now as the documentation of the project into a thesis format is in full swing, it has been interesting to recap everything that has been done in the past months and see the project as a complete entity. The most important outcomes of the project for me – in addition to learning to trust myself in planning scientific experiments – have of course been all that I have learned on the topic itself and becoming more secure with the characterisation methods I used. Once the thesis is finished, I am eager to continue working with similar sustainability-centred topics with material science in the future as well!